Tootekirjeldus

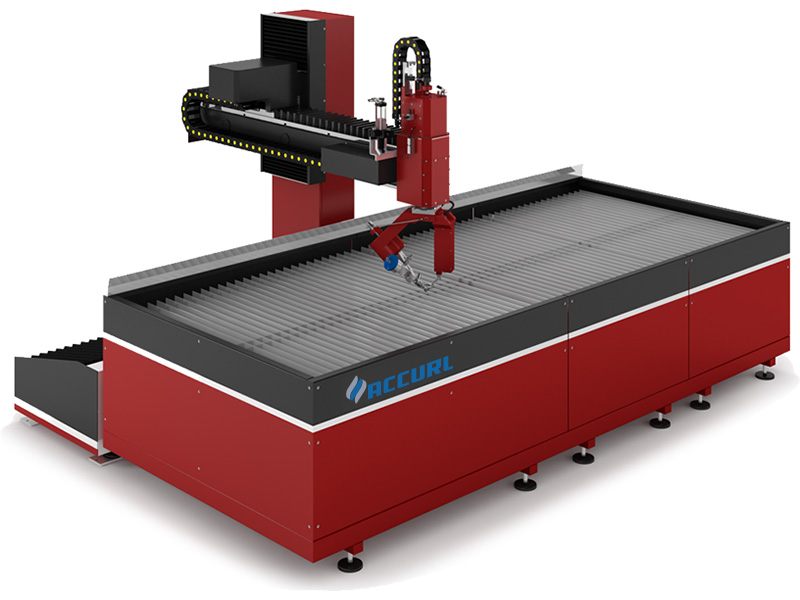

ACCURL® abrasiivne veejoaga masin on kõrgsurvega veejoaga masin, mis kasutab mitut tüüpi materjalide lõikamiseks otsest veejoaga lõikamist või abrasiivset veejoaga lõikamist. ACCURL® on raskeveokite täppis, maandatud kuulkruvi süsteem, mis tagab maksimaalse täpsuse ja jäikuse. ACCURL® on ehitatud vastavalt tööpinkide tööstuse kõige rangematele standarditele. .

ACCURL®, kasutades veejoa kõrgsurve lõikamisprotsessi materjali paksuse lõikamiseks manomeetrist kuni 8 ".

ACCURL® lõikab selliseid materjale nagu alumiinium, soomusplaat, messing, vaip, vask, klaas, graniit, nahk, marmor, pehme teras, plast, roostevaba teras, kivi, plaat, titaan...

Täiuslik veejoa lõikamine :

ACCURL® Waterjet mehaaniline töötlemine saavutatakse suure surve all suure koguse vee sundimisega läbi väikese otsiku düüsi. Otsikust väljuv kiirenenud vee aur mõjub materjalile ja alustab lõikamisprotsessi. Kiirendatud veevoolust pärit kerf on äärmiselt kitsas. Seejärel kontsentreeritakse see rõhk väikesele pinnale materjalile, mis hakkab materjali erodeerima. Pehmemaid materjale saab lõigata veesurvega. Kõvemad materjalid vajavad abrasiivse etteandesüsteemi kasutamist, näiteks metalli lõikamine. Abrasiiv sisestatakse kõrgsurveveevoolu, mis seejärel käivitab kõvemate materjalide erosiooni. Ehkki veejoa töötlemine on aeglaseim lõikamisprotsess, on selle eeldatava tempo ületamiseks kindlad eelised:

• puudub kuumusest mõjutatud tsoon

• Mehaanilised pinged puuduvad

• väga kitsas Kerf

• Pole vaja sekundaarseid toiminguid

•Sile pind

• Oskab lõigata mitmesuguseid materjale

• Oskab töödelda erakordselt detaile

• Minimaalne materjali kaotus

•Keskkonnasõbralik

Põhijooned

Kiire, tõhus ja täpne ACCURL® Center pakub tipptasemel jõudlust paljudest materjalidest keeruliste detailide veejoaga töötlemisel. Lihtsatest metallidest kuni keeruliste komposiitideni – end tõestanud 4-tolline 7-tolline ruudukujuline lõikeala on ideaalne kiireks prototüüpimiseks ja väikeste ja keskmise suurusega osade õigeaegseks tootmiseks. Lihtsa kinnituse ja hõlpsa juurdepääsuga lõikelauale lühendavad seadistamisajad oluliselt, suurendades tootlikkust ja kasumlikkust.

• Kiireimad lõikekiirused ja parim täpsus võrreldes kõigi tööstusharu abrasiivjoaga ning seda toetab meie eksklusiivne NAIKY PCIMC-6A® tarkvara koos reaalsete lõikeandmetega

• Programmeeritav mootoriga Z-telg koos täpse ACCURL® 5i otsikukoostuga võib suurendada lõikamise tootlikkust ja protsessi tõhusust

• Tilt-A-Jet® koonust kompenseeriv abrasiivjoaga lõikepea (saadaval lisavarustusena)

• Precision XY Axis jäigalt lõikelauale kinnitatud

• Eelkoormatud lineaarlaagrid ja täppis-kuulkruvid

• Vähe hooldust vajav, kõrge töökindlusega kääritaoline kõva torustik

• Ajamisüsteem on tihendatud vee, mustuse ja liiva eest

• Operaatori lihtne juurdepääs tööalale

• Suure tõhususega USA 4. põlvkonna Hypertherm ® pumbasüsteemid, mis on saadaval 30, 40 või 50 hj, töötõhususega kuni 90%.

• Tugev ja täpne konstruktsioon väikese tolerantsiga lõikamiseks ja usaldusväärseks tööks

• Kiire veetaseme reguleerimine vaikseks ja puhtaks sukellõikamiseks

• Massilise abrasiivi kohaletoimetamise süsteem transpordib granaadi sõlme suurest punkrist Z-teljel asuvasse nullseisuaega punkrisse

• Valikuline muutuva kiirusega tahkete ainete eemaldamise süsteem (VS-SRS), mis on mõeldud raskeks tööstuslikuks kasutamiseks, suurendab tööaega tänu tahkete ainete automaatsele eemaldamisele

• Tarnitakse täielikult eelmonteeritud ja tehases testitud süsteemina

Üksikasjad:

Masina raam

MAX-seerial on kere, mille elektrilised komponendid on kindlalt masina kere sisse ehitatud. See ainulaadne monoplokkkonstruktsioon võimaldab lihtsat paigaldust ja paindlikkust süsteemi paigutamiseks paljudesse kohtadesse.

Servoajam ja mootor

Imporditud servomootor (Y-telg, mida käitavad kaks servomootorit) koos keeruka planeedireduktoriga tagab ühtlase, täpse ja usaldusväärse ajami.

Pöördmutriga kuulkruvi

Täpsed kuulkruvid on suure töökindluse ja korratavusega, mis suurendavad jõudlust ja täpsust.

Lõikepead USA Hypertherm

IDE-pea on üks, hõlpsasti kasutatav tükk. Üksik lõikepeaosa koosneb korpusest, teemandiavast ja segamiskambrist. Sellel on 90-kraadine sisselaskeava, mis hoiab ära abrasiivi kogunemise peas. Sellel on tasane tihend isegi düüsitoru külge, mis välistab ava purunemise ohu. See on väga kasulik ettevõtetele, kus on mitu veejoa operaatorit

Kiirdetailid

Seisund: uus

Päritolukoht: Anhui, Hiina (Mandri)

Kaubamärk: ACCURL

Mudelinumber: MAX-WJ-2515D, MAX-WJ-2515D

Pinge: 380V 220V Valikuline

Nimivõimsus: 7,5 KW

Mõõdud (L * W * H): 3880 * 2150 * 2000 mm

Kaal: 6500 kg

Sertifikaat: CE ISO SGS FDA

Garantii: 3-aastane garantii

Pakutakse müügijärgset teenindust: masinate hooldamiseks välismaal asuvad insenerid

Võimendi koost: Hypertherm USA

Portaali tüüp: laud

Efektiivne lõikeala: 1500x3000mm

Vahelduvvoolu servo draiver: MITSUBISHI Jaapanist

Kuulkruvi ja lineaarne juhtsiin: HIWIN, TAIWAN

Vahetusventiil: Rexroth Saksamaalt

Pumba peamine mootor: Siemens Saksamaalt

CNC-kontroller: AI, DST, DWG, DXF, DXP, LAS