Kiirdetailid

Kiirdetailid

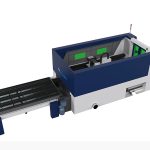

Kasutamine: laserlõikamine

Seisund: uus

Laseri tüüp: kiudlaser

Materjal: metall

Lõikepaksus: 0-30mm

Lõikamisala: 1500 * 3000mm

Lõikamiskiirus: 35m / min

CNC või mitte: jah

Jahutusrežiim: vesijahutus

Juhtimistarkvara: Bodor Pro

Toetatud graafiline formaat: AI, DXF, PLT

Päritolukoht: Shandong, Hiina (Mandri)

Brand Name: Bodor

Model Number: P3015

Sertifitseerimine: CE, ISO, SGS, FDA, BV, TUV

Pakutakse müügijärgset teenindust: masinate hooldamiseks välismaal asuvad insenerid

Laservõimsus: 500W / 1000W / 1500W / 2000W / 3000W / 4000W

Märksõna: laserlõikur

Laseri allikas: IPG / MAX

Garantii: 3 aastat

Suurus: 9950 * 3050 * 2200mm

Kaal: 11000Kg

Tööpind: 1500 * 3000mm

Eluaeg: Rohkem kui 20 aastat

Jahutus: vesijahutus

Pidev tööaeg: 24 tundi

Meie laserlõikusmasina omadused

1. täielik kaitsekate

Environment friendly and Healthy

Full closed protection improves using security; laser protection glass isolates laser radiation to human beings; automatic collection system of smokes and dusts is environment friendly; intelligent monitoring system reduces accident rate, making us enjoy beauty and health in cutting process.

2. kaks automaatset vahetusplatvormi süsteemi

aja kokkuhoid ja vaeva vähendav

Kiire andmevahetus kahe platvormi vahel parandab oluliselt töö efektiivsust. Rackide ja hammasrataste ülekandesüsteem on parema jäikuse ja suurema täpsusega, säästes söötmise aega, muutes töötamise tõhusamaks.

3. Välimuse kujundus

Surrounded by baking paint silver decoration,coordinated with diamond cutting tempered glass and alpine white sheet metal design, the international design of the machine is accepted by global consumer groups.The workplace is neat, orderly and space-saving.

4. cast iron bed

Integraalselt moodustatud, jätke splaissimine

Kasutatakse helbegrafiitmalmi, mille väikseim tõmbetugevus on 200MPa. Kõrge süsinikusisaldus, kõrge survetugevus ja kõrge kõvadus. Tugev löögi neeldumine ja kulumiskindlus. Hea valamise ja lõikamise jõudlus. Suurepärane määrimine, korrosioonikindlus ja mõõtmete stabiilsus. Madal termiline tundlikkus ja voodivahe tundlikkus vähendavad seadmete kadu kasutamisel, nii et masina täpsus säilib pikka aega ja elutsükli jooksul ei esine deformatsioone.

5. Autofookusega laserpea

Vabastage oma käed ja nautige autofookust

(1) Auto focus

Kasutatav erinevatel fookuskaugustel, mida juhitakse tööpinkide juhtimissüsteemiga. Fookuspunkti kohandatakse lõikamisprotsessis automaatselt, et saavutada erineva paksusega lehtmetallide parim lõikamisefekt.

(2) Free

Focal length is controlled by operating system. We don’t need to do manual regulation, which effectively avoids errors or faults caused by manual operation.

(3) Fast

See suudab automaatselt reguleerida tööprotsessis kõige sobivamaid fookuspunkte, parandades oluliselt lõikekiirust;

Erinevate materjalide või erineva paksusega lehe asendamisel peab käsitsi teravustamise laserpea fookuskaugust käsitsi reguleerima, väga ebaefektiivne; autofookuse laserpea suudab automaatselt lugeda süsteemi salvestusparameetreid, väga tõhus;

(4) Accuracy

Suurenev perforatsioonifookuse pikkus, perforatsioonifookuse pikkuse ja lõikefookuskauguse eraldi seadistamine parandavad lõikamise täpsust.

(5) Durable

Sisseehitatud topelt vesijahutusstruktuurid tagavad kollimeerivate ja teravustamiskomponentide püsiva temperatuuri, väldivad läätsede ülekuumenemist ja pikendavad objektiivide kasutusiga.

Suurenev kollimatsiooni kaitselääts ja fookuskaitselääts, kaitske põhikomponente hoolikalt.

6. Operating system display

Elegantne välimuskõver

Esimene, mis kasutab maailmas kasutajaliidese disaini, mis võimaldab kuval reageerida töötlemistabelile, muutes töötlemise intuitiivsemaks. Elegantsed kõverad sobivad täpselt masina kerele. Tugev veekindel hingav süsteem loob parima ruumi, muutes töö mugavamaks. Teemantlõikeprotsess ja HD-plasma karastatud klaas muudavad ekraani peenemaks ja mugavamaks kasutamiseks.

7. Cast aluminum crossbeam

Integreeritud terasest survevalu, kerge, paindlik ja tõhus

Pärast kunstlikku vanandamist, lahusega töötlemist ja viimistlemist on risttalal hea terviklikkus, jäikus, pinna kvaliteet, sitkus ja elastsus. Alumiiniumsulami kerge kaalu ja tugeva jäikuse metalliomadused on abiks töötlemisel kiirel liikumisel ning kõrge paindlikkus on kasulik erinevate graafikate kiireks lõikamiseks suure täpsuse alusel. Kerge risttala võib anda seadmetele suure töökiiruse, parandades töötlemise tõhusust, et tagada töötlemise kvaliteet.

| Töösuurus | 1500 * 3000mm |

| Laservõimsus | 1000/1500/2000/3000 / 4000w |

| Masina suurus | 9950 * 3050 * 2200mm |

| Kaal | 11000 kg |

| Maksimaalne liikumiskiirus | 100m / min |

| Max lõikekiirus | 35m / min |

| Min liini laius | 0,1 mm |

| Lõikamissügavus | 0,2-6mm |

| Jahutav viis | Vesijahutus |

| Sõidu- ja ülekandeviis | Imporditud servomootor |

| Pidev tööaeg | 24 tundi |

| Positsioneerimistäpsus | 0,03mm |

| Positsioneerimistäpsus | 0,02mm |

Taotlusmaterjalid:

It is suitable for cutting carbon steel, stainless steel, aluminum, copper and alloy metal materials

Rakendusvaldkonnad:

The equipment meets the parts processing requirements of most industries, working accuracy is stable. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.